Special Competencies

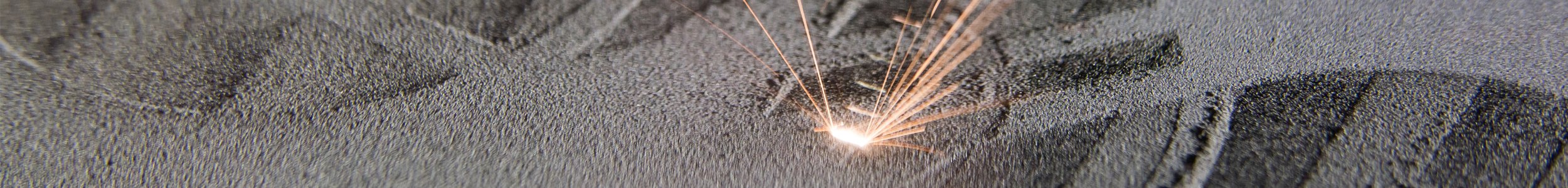

Our highly qualified team shows its entire professional depth in producing functional surfaces. It is often the surface properties that determine the quality of the overall part. Precision parts from PWB fulfill your most stringent requirements for surface properties – whether they relate to sealing, strength, wear behavior, or contact stiffness. These also include their suitability for coating and finishing.

At PWB, we can process nearly any material to your specifications. All it takes is the know-how of our employees who operate our machinery and possess full mastery of the relevant parameters. Whether we are processing aluminum, steel, or high-performance composites, what counts for us in the end is precision.

Material selection

- Aluminum alloys (including Dispal, etc.)

- Steel types / rust-resistant and stainless steel / Inconel, etc.

- Engineering polymers

- Composites (thermoplastic CFRP, Vetronit, GFRP)

- Nonferrous metals (e.g. brass, bronze, copper)

- Casting alloys (aluminum, cast iron, etc.)

Wherever motion is needed, our piston rods offer high performance. In our fully automated piston rod manufacturing, we produce standardized precision parts which meet the most demanding requirements for material quality and surface composition. We put the finishing touches on surfaces with subsequent finishing technologies such as ball polishing, roll burnishing, and superfinishing.

PWB’s expertise in fluid technology is just what is needed to implement hydraulic or (especially) pneumatic drive solutions, valve solutions, or guide units. We process various materials to make parts operated by compressed air or entire assemblies which are used for a broad range of applications. Whether they are used for compressed air brakes, pneumatically driven tools, or positioning technology, our expertise in fluid technology assures you maximum precision for complex geometries with very tight tolerances and perfect surfaces.